Rubber Conveyor Belts

MISSION STATEMENT

QUALITY POLICY

- Standard manufacturing process in tune with global technologies.

- Consistently high quality products with continuous R&D.

- Exceptional emphasis on client satisfaction.

Established in the year 1997 We have an in-house facility for finished products coupled with skilled and will qualified engineers, to Vulcanise conveyor belts ideally suitable for various applications like Steel, Coal, Mining, Food Processing, Cement, Fertilizers Paper Industries etc.

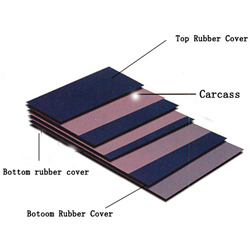

CONVEYOR BELTING

We the conveyor belts with the following reinforcement material coupled with the most appropriate cover grades for various applications and extraordinary service conditions. Synthetic fabric reinforced: Nylon/Nylon-N/N Polyster/Nylon-EP 2. Cotton/Cotton reinforced: We offer belts in width ranging upto 1200mm.

IMPROVED TROUGHING RESULTING IN HIGHER CAPACITY UTILIZATION:

Due to excellent transverse flexibility of Vair synthetic conveyor belt, deep troughing of carcass is possible which increase volumetric transfer capacity.

EXCELLENT ROT RESISTANT CONVEYOR BELTS:

Eliminates problem of mildew action on carcass, ensuring total protection against the damaging effects of moisture, even under severe wet conditions wherein fabric deterioration is virtually eliminated.

HIGH ADHESION LEVELS

This is possible by utilising the inherent nature chemical bonding, which provides adhesion between cover to ply and ply to ply, Consequently, it contributes to edge wear resistant higher edge and carcass consolidation and eliminates cover peeling and ply separation.

GREATER IMPACT RESISTANCE

The increased inter ply rubber thickness maximizes the impact absorption and reduces carcass damage. The outstanding impact resistance makes the use ur breaks redundant.

SUPERIOR EDGE DESIGN

Since synthetic fabric is totally rot resistant, the cut edge construction and the hardwearing exposed nylon givegiceacriter resistance to edge damage. Hence, Rubber synthetic conveyor belts are recommend with cut edge construction, as they will perform effectively even under the most adverse environments.

CONTROLLED BELT GROWTH

Rubber synthetic conveyor belt is manufactured with the best quality of fabrics to minimize elongation and to ensure controlled belt growth in service.

STORAGE

Rubber synthetic conveyor belts are resistant to moisture and they can be stored outdoors in original packaging for limited periods only, as longer periods may results in premature ageing of the belting. However, the stored belts should not be exposed to direct sunlight, oil, grease, solvents and acids as this can damage the belts.